Spring Return Dosing Pumps

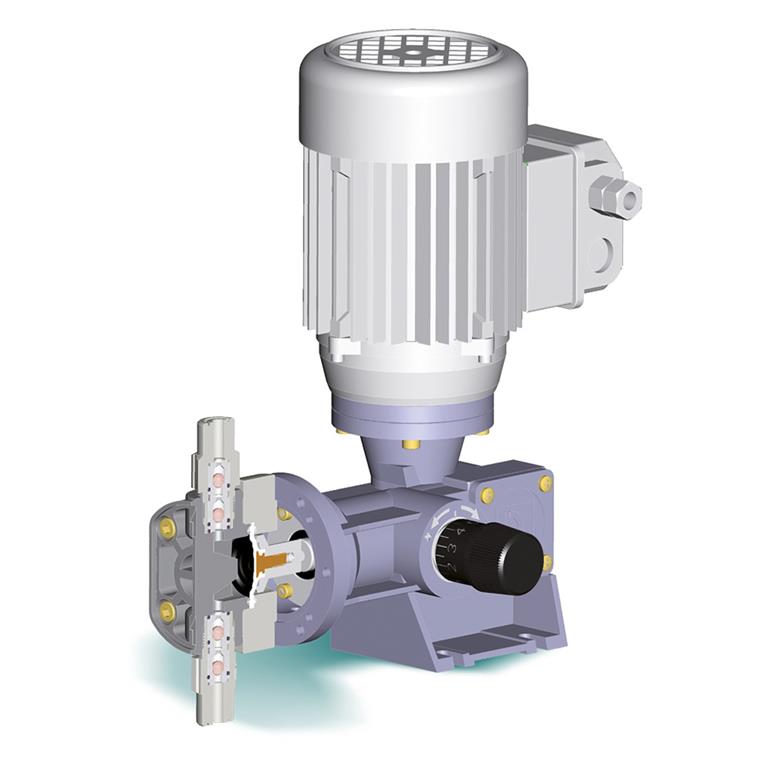

When we categorize electromechanical (motorized) dosing pumps based on their working principle, the first type we encounter is the "spring-return dosing pumps," which are widely used in industrial processes. As is known, electromechanical dosing pumps operate on the principle of transferring power from an electric motor to a diaphragm or piston that enables chemical transfer through mechanical means. The power provided by the electric motor is transmitted to the gear set inside the electromechanical dosing pump body via a worm screw. This gear set begins to move in a non-linear (elliptical) manner inside the body with the momentum received from the worm screw.

These movements are intended to impart motion to the piston, which extends from the pump body to the dosing head and passes through a spring. With each contact of the gear set, which rotates in elliptical movements, the piston moves forward, while upon completion of the movement, the spring pushes the piston back into the body, ensuring the completion of the movement necessary for chemical dosing. Generally, many different pump models within this group can achieve a capacity of 1000 liters/hour and a pressure of up to 250 bar. The appropriate pump model is selected based on the fluid, capacity, and process pressure differences.